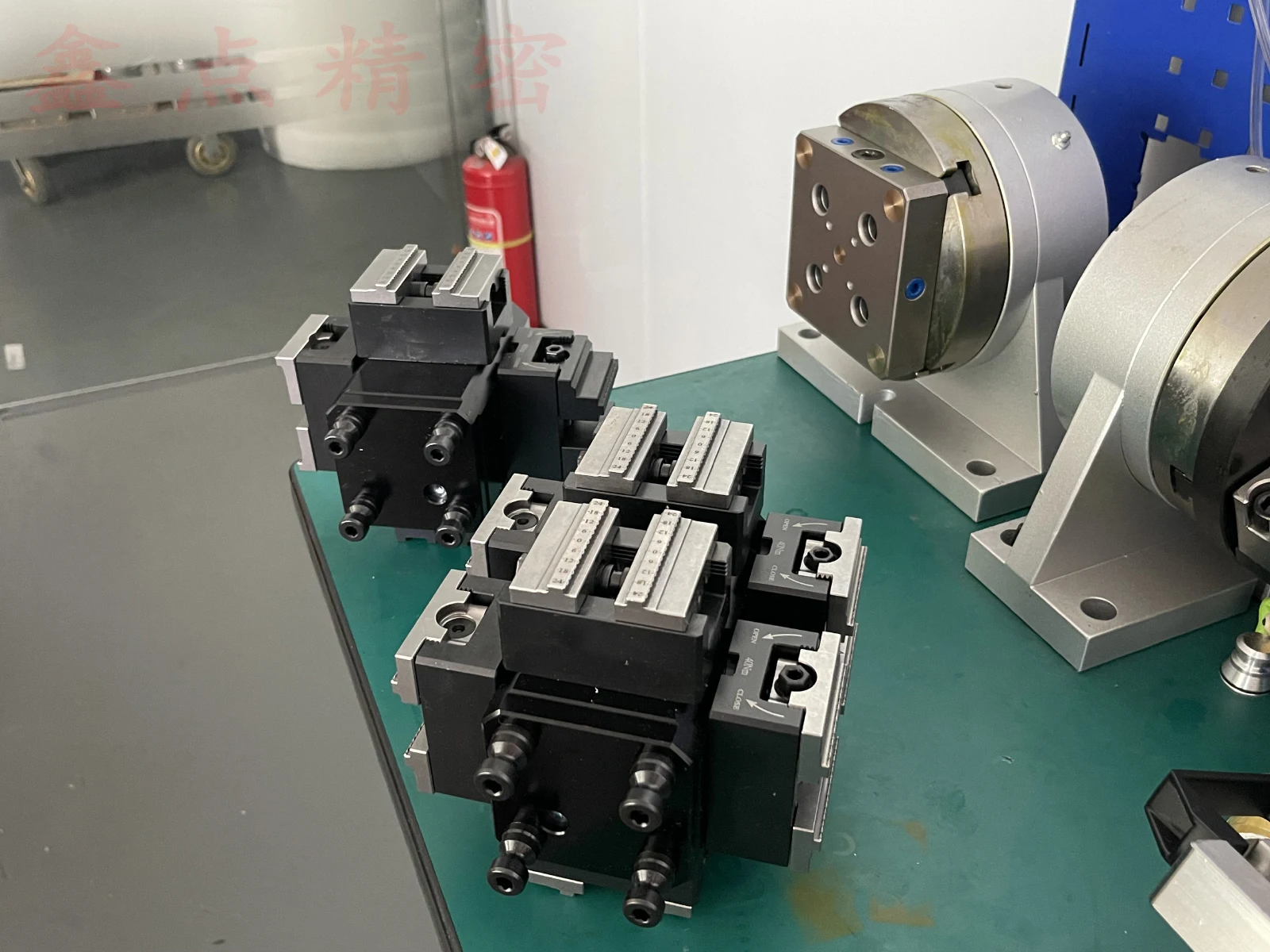

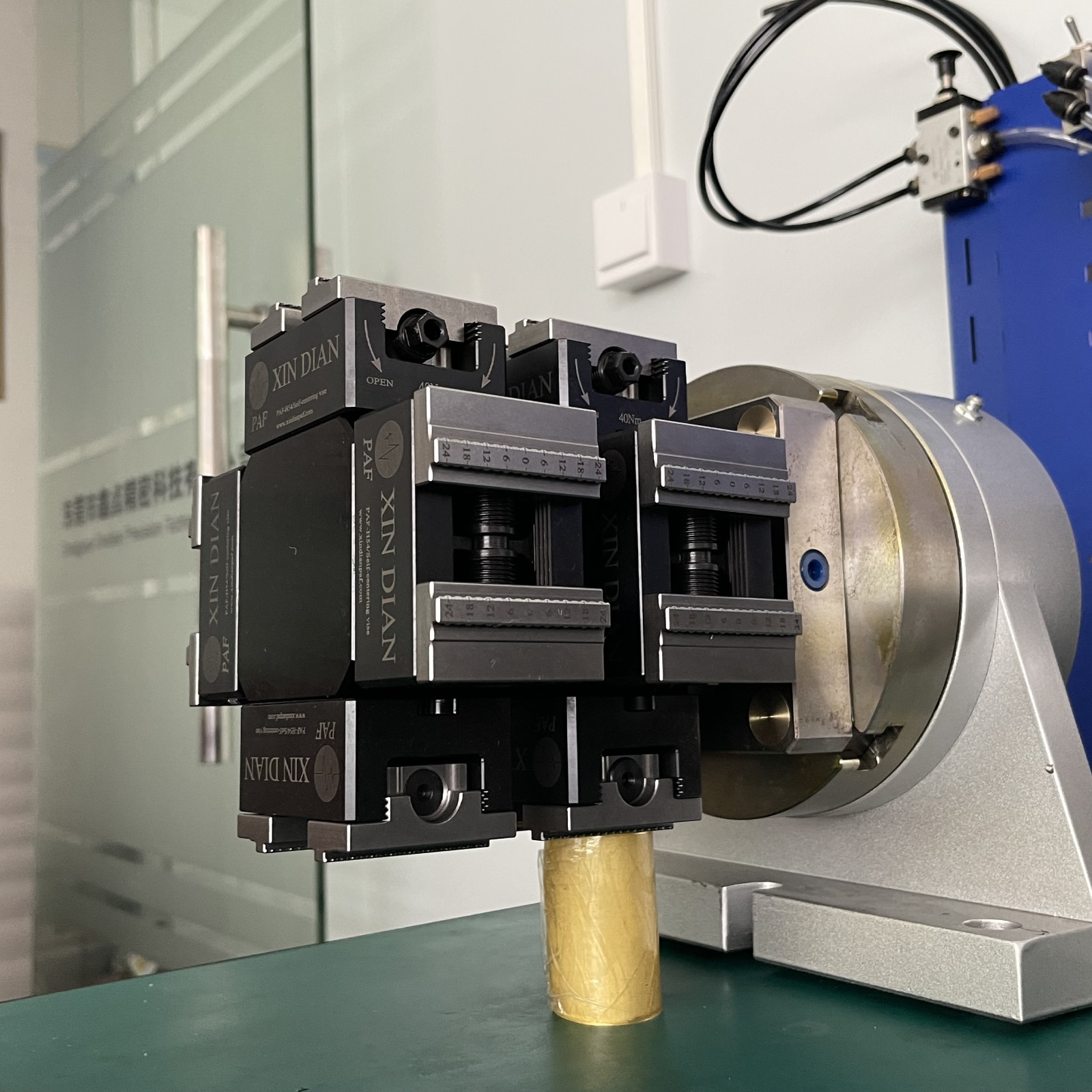

- Number of Jaws: 4

- Power: Manual

- Origin: Mainland China

3D model file:

https://drive.google.com/file/d/1Kn3iNpS0tfPoDfAZ5ptrFO9pOX21hb_s/view?usp=share_link

Note: DDU does not include import duty and customs clearance

1. We only charge product price and shipping fee

2. Please confirm that you have the ability to clear customs before purchasing.

It is best to use the company name to receive

3. If it is returned due to inability to clear customs, the round-trip shipping fee shall be borne.

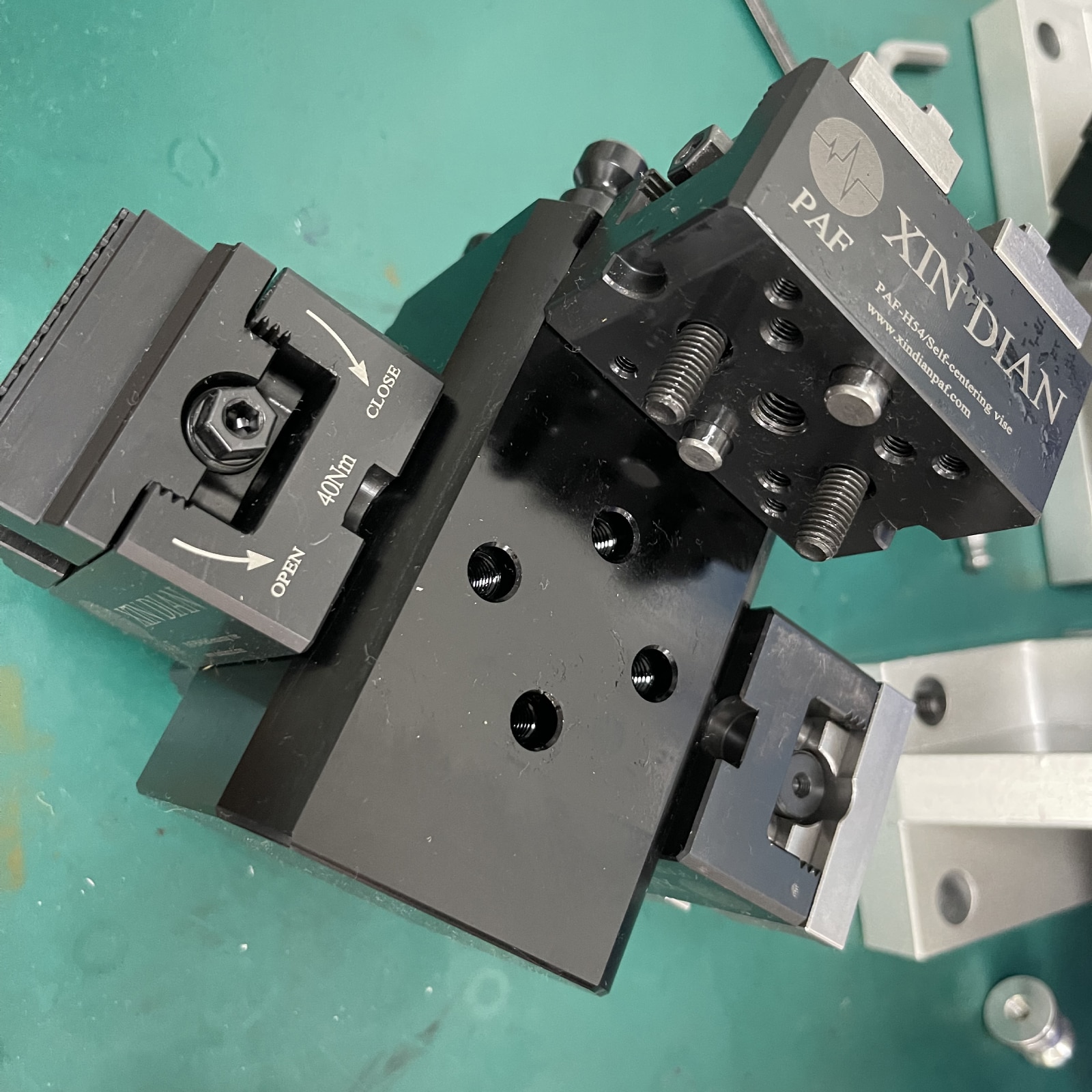

Precautions for product use:

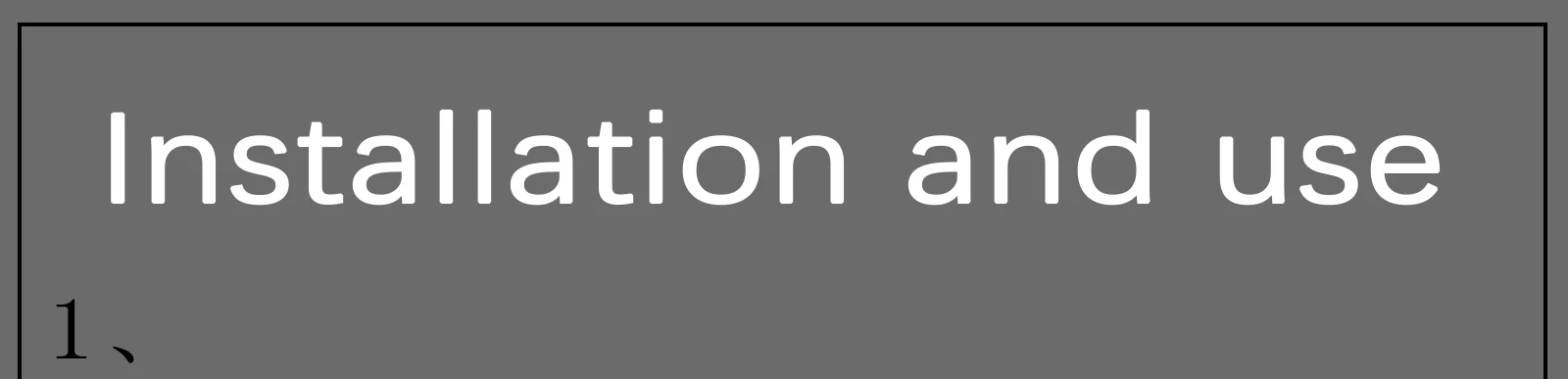

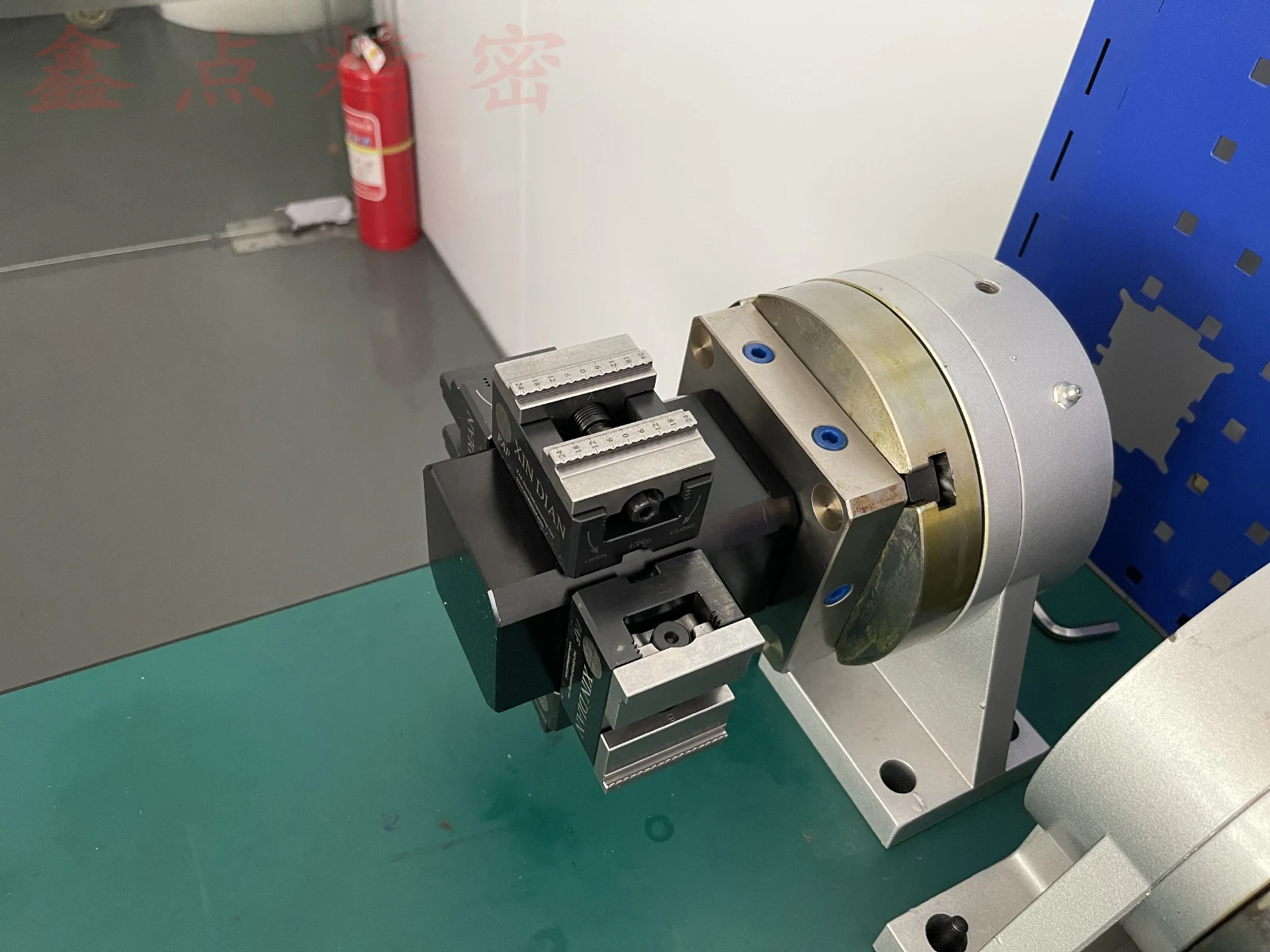

1. The vice is installed on the column through the customized mounting hole.

(Single order vice only send standard vice. Without mounting hole)

2, vice can clamp copper, aluminum and other soft materials, not recommended to use steel parts.

3. When tightening the vise, you must use a socket wrench, which is easy to damage when tightening with an hexagonal wrench.

4. There is 0.03 gap between guide rail and lead screw, and the vice rises 0.03. Please order carefully!

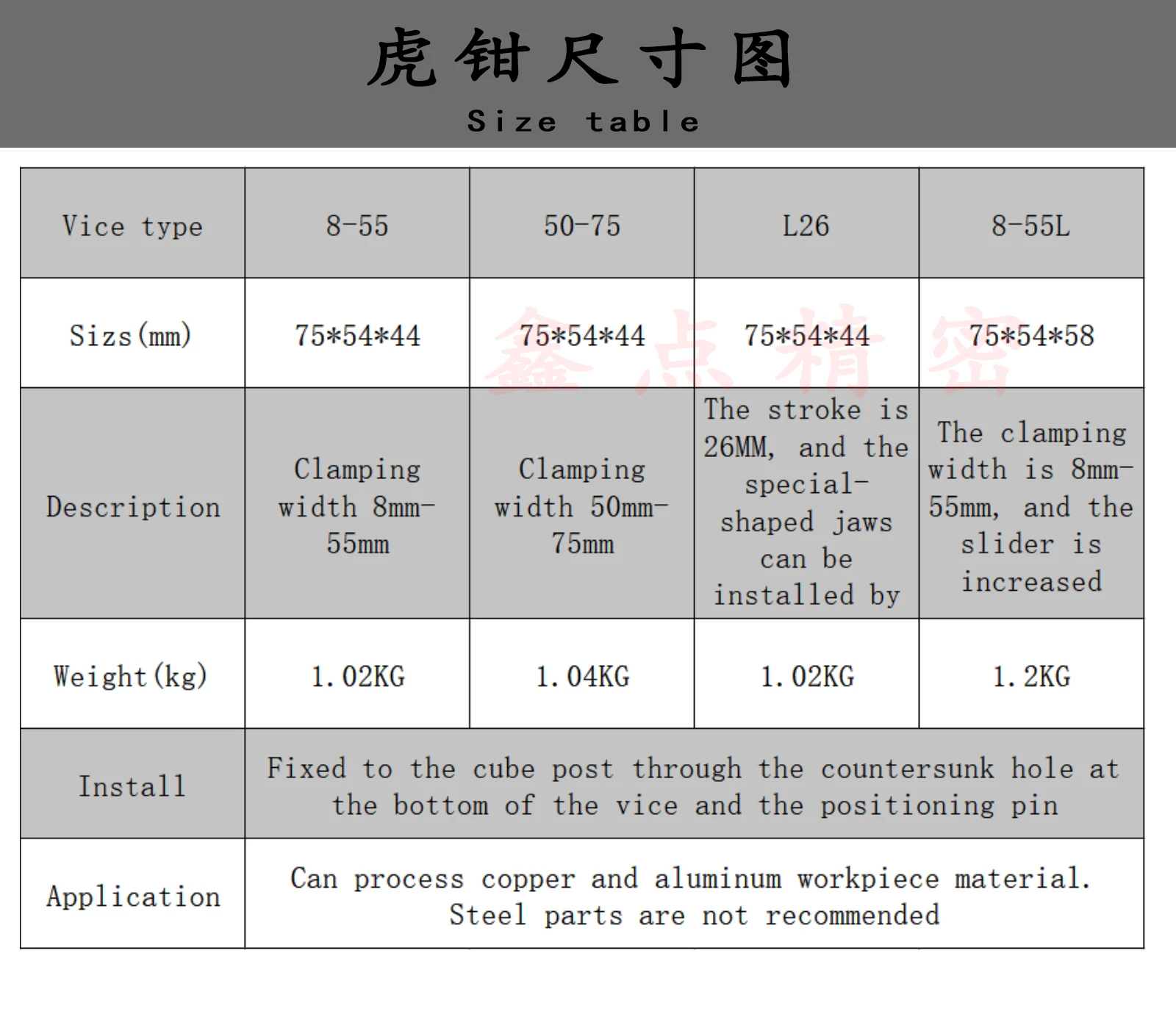

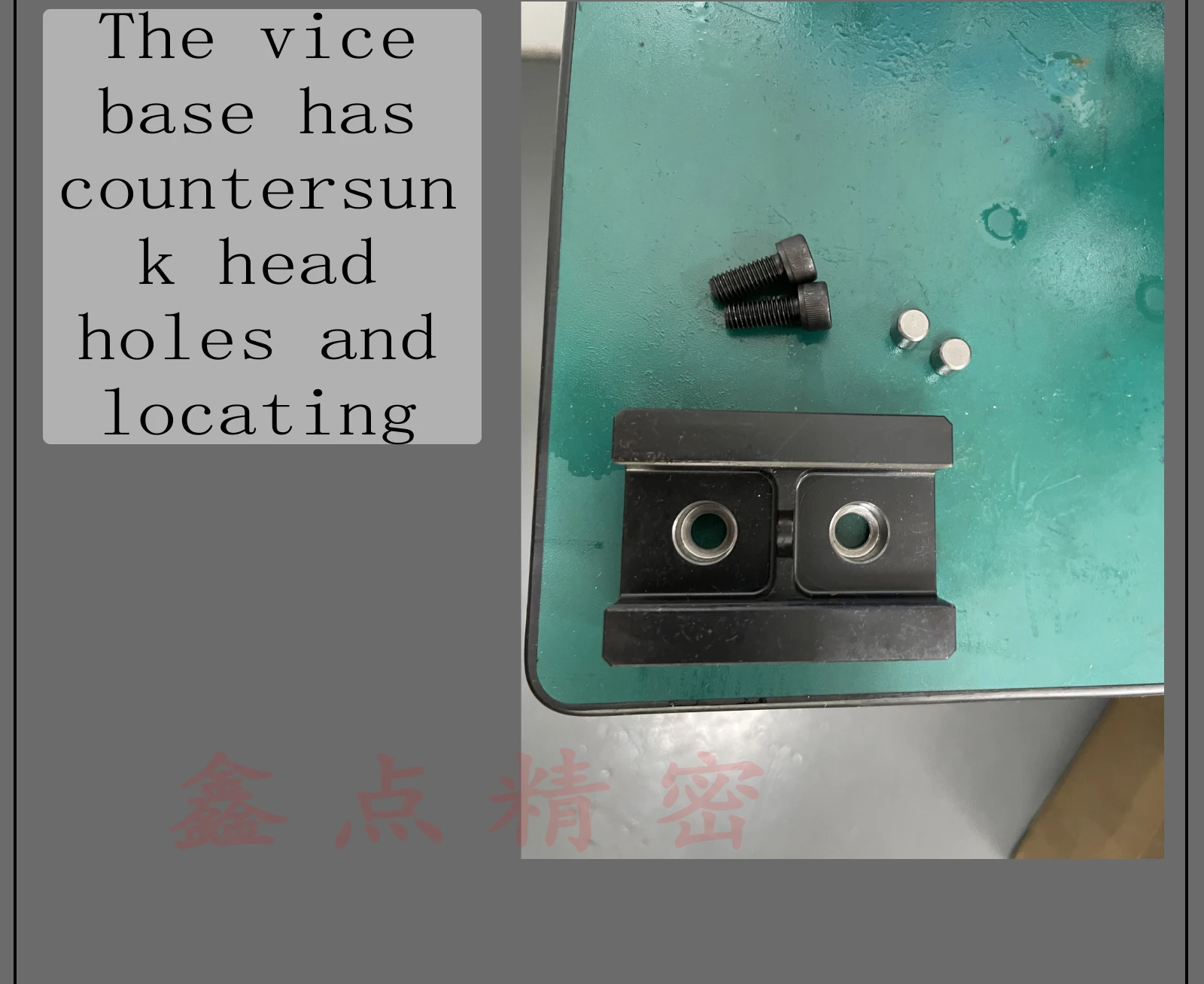

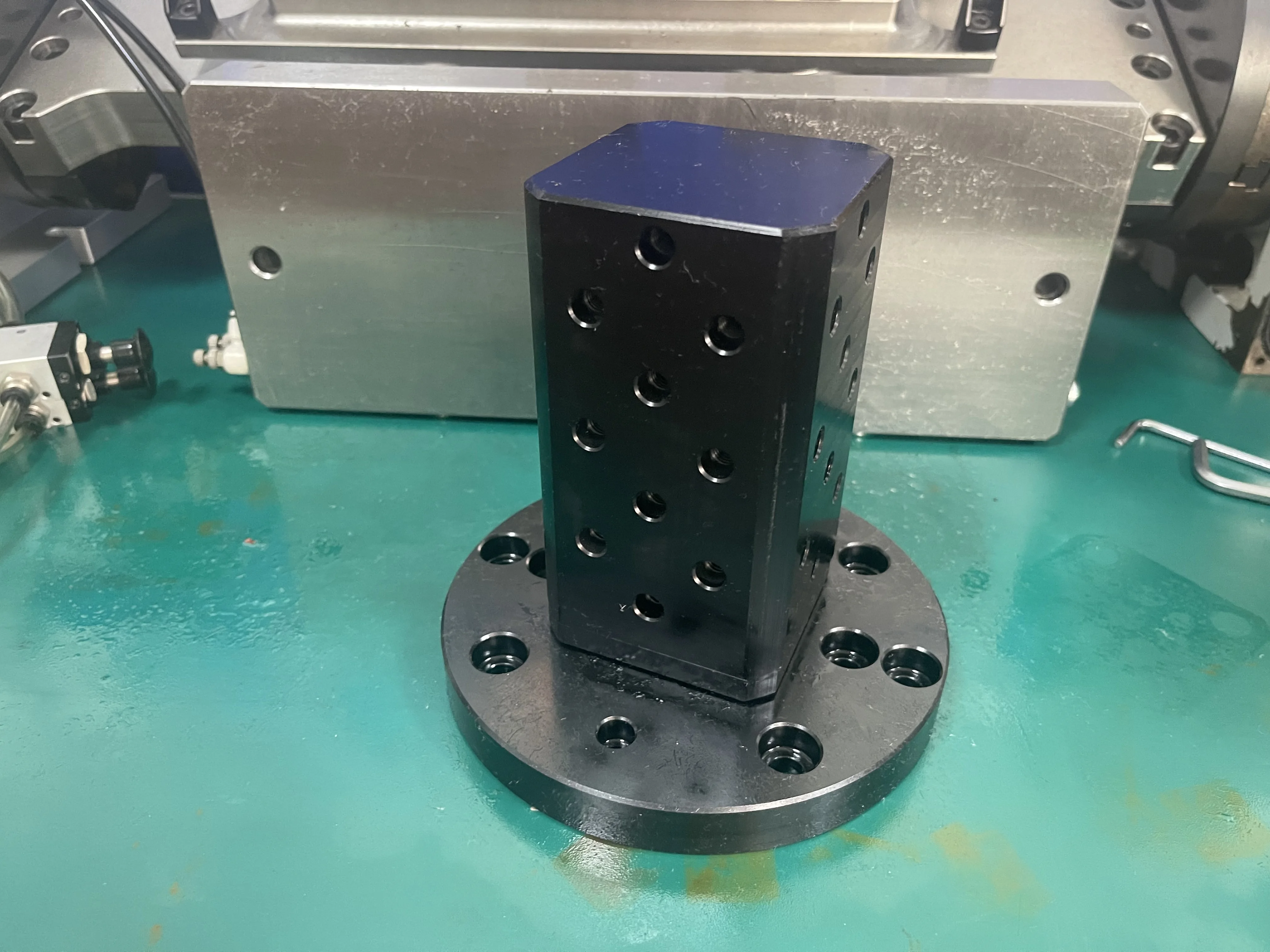

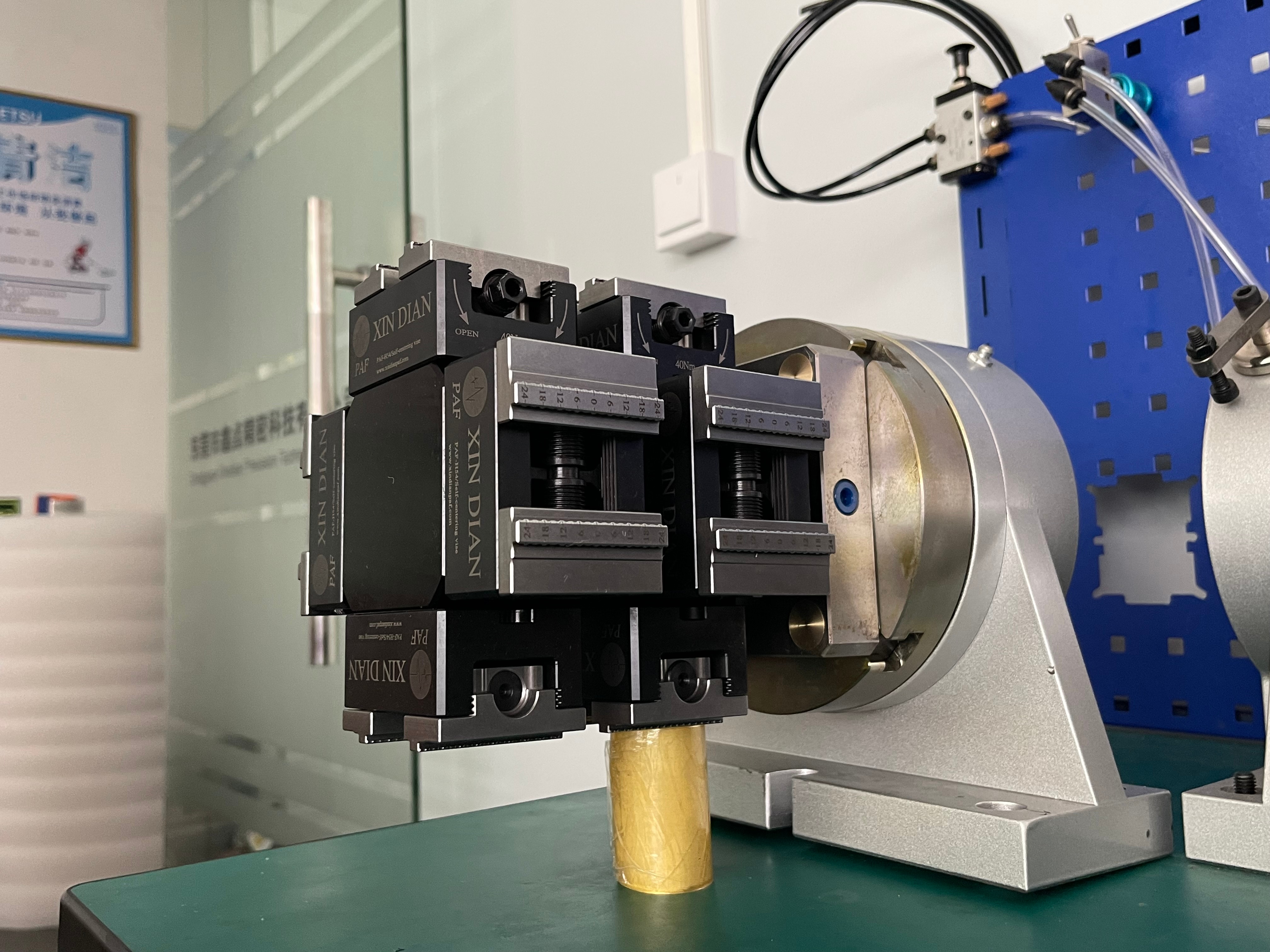

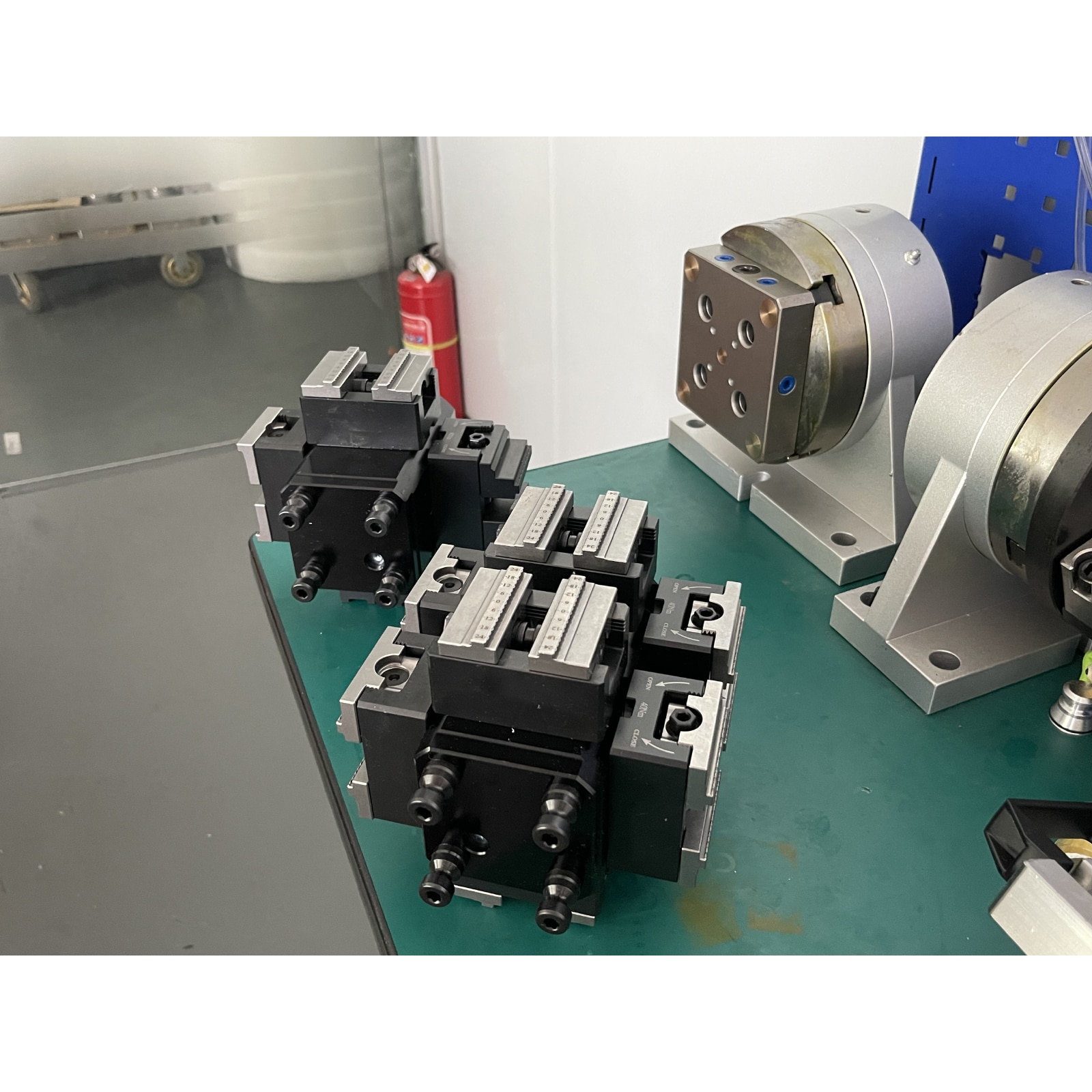

Zero point quick change system · Vertical base

Batch product processing, multi - station clamping

When the center of the four-axis tailseat is higher than 135, the product works normally.

The whole set of products includes vertical base, self - centering vice, zero - point positioning plate.

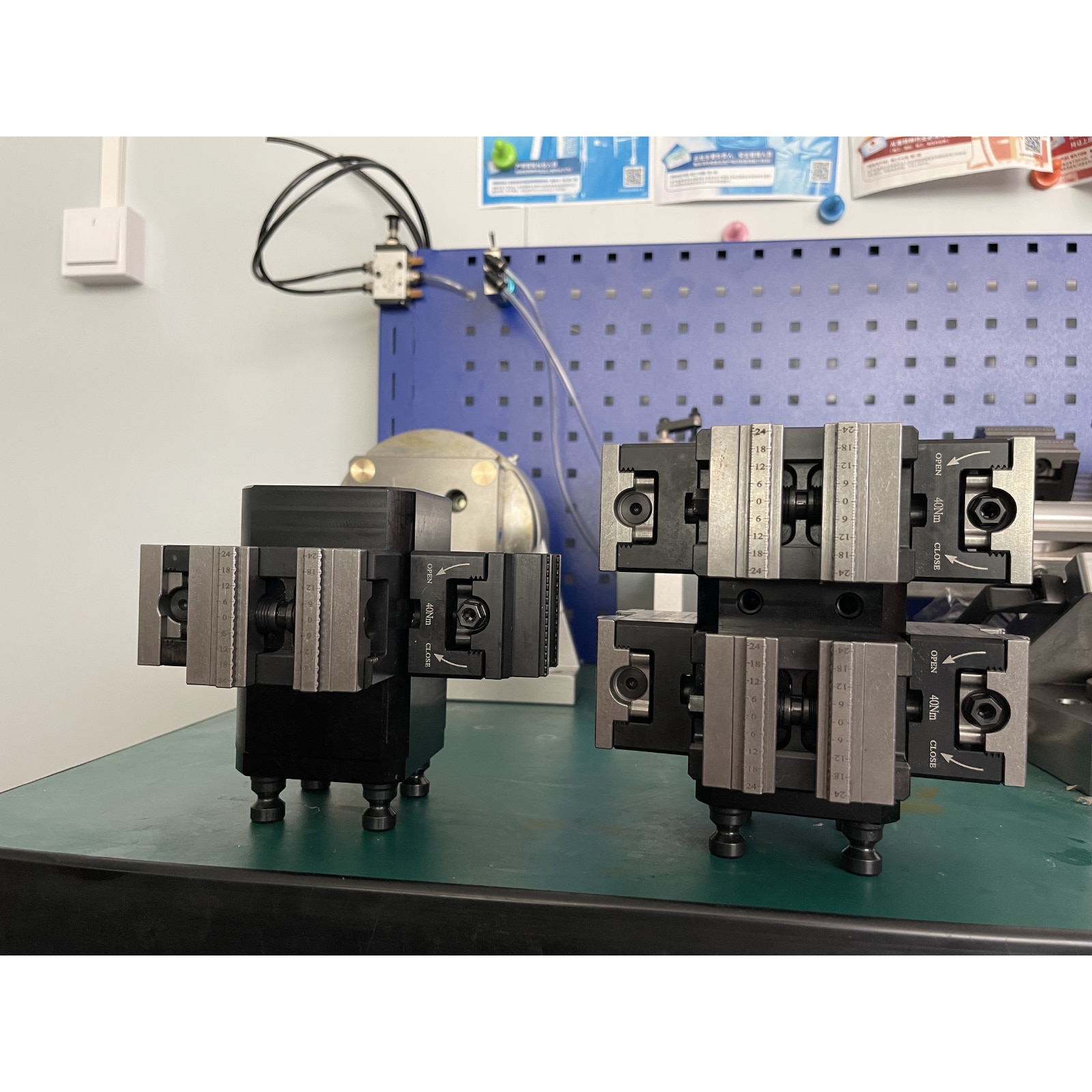

Model:(D52-4S)(D52-8S)

Sizs (mm):(80*80*127)、(80*80*147)

weight (kg):(2.06KG)(2.3KG)

Application:(Install 4pieces ofVice)(Install 8pieces ofvice)

Material:6061 Aluminum

Install:Connect with zeropositioning plate through 4D52 nails or make switchingplate by oneself

Application:The number of parts in eachcycle can be maximized

Three installation methods:

1、Compatible with D52 zero point positioning quick change base.

2、Compatible with D125 adapters。

3、Compatible with D170 adapters。

Reviews

There are no reviews yet.